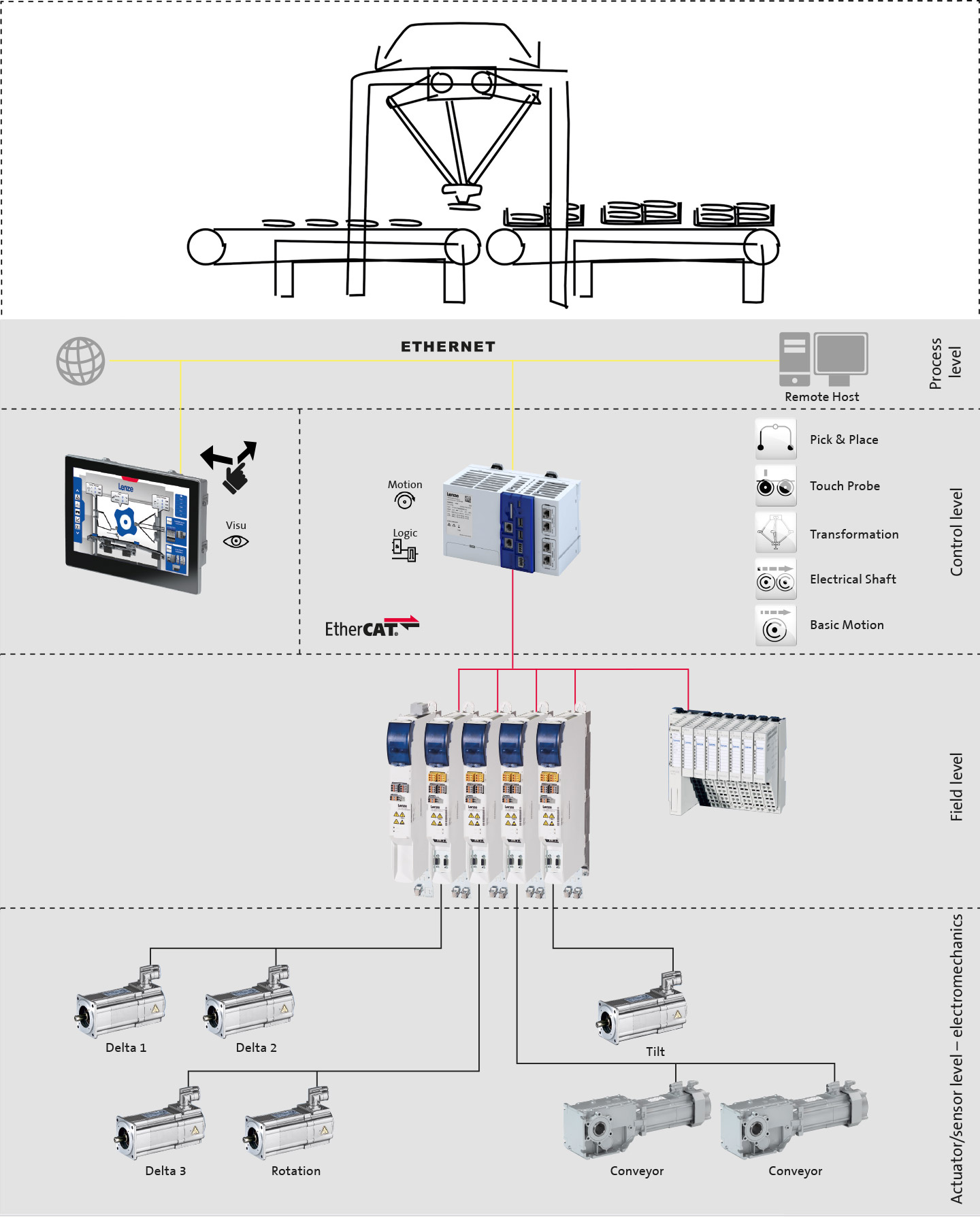

Delta robot: Maximum flexibility due to robotics.

- As a flexible component of a machine, the Delta robot is the very first choice for customised production.

- Lenze FAST technology modules enable parameterisation instead of programming - without any deep knowledge of robotics. We thus create software complexity that is easy to handle.

- Openness of our software: You remain independent and are able to contribute your very individual core competence.

- Integrative control combines logic, motion and robotics in one controller. This eliminates costs and engineering work for additional controllers.

- Easy linkage of peripherals such as cameras, conveyor belts etc.

- Uncomplicated connection to the MES/ERP system for e.g. track-and-trace functionality, recipe management, machine management.

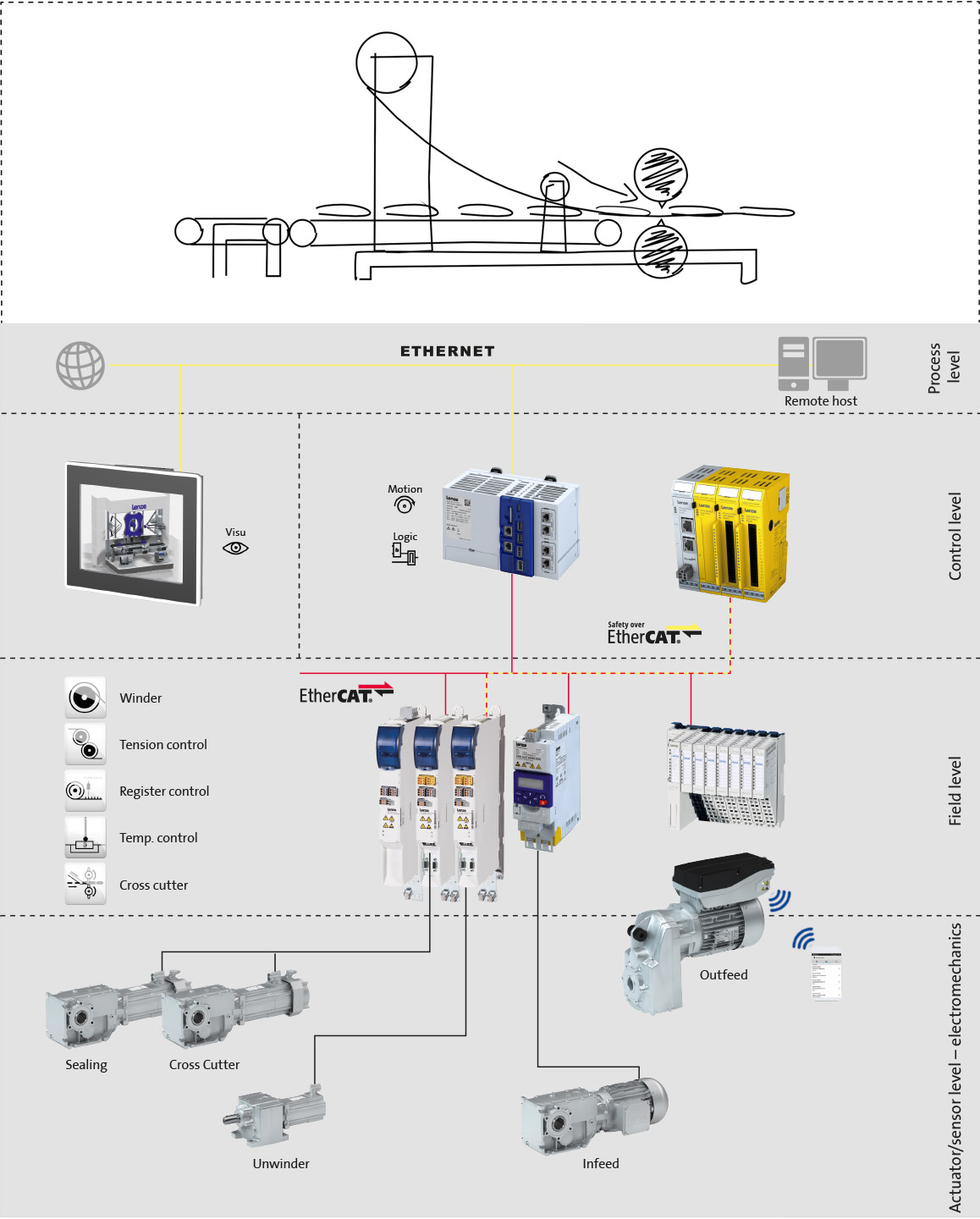

Horizontal bag form, fill and seal machine: Efficient use of resources and maximum productivity

- Modular and scalable software and hardware can be adapted to any requirements.

- The winder solution from Lenze compensates for problems such as friction and the influence of acceleration. This prevents material cracks/wastage and enables the use of thinner films that are sensitive to pulling. And all this without any additional costs for special sensors that are used to measure tensile force.

- Intelligent drives: The machine gets to know the parameters of the drive technology during the process. These parameters no longer need to be determined by means of time-consuming and costly expert tests.

- If the packaging material or humidity changes, the machine adapts itself accordingly.

- The predefined "Cross cutter" technology module calculates the cam for the synchronous movement of a cross sealing roller and synchronises it with the master axis. Empty packages and products between the sealing jaws are prevented.

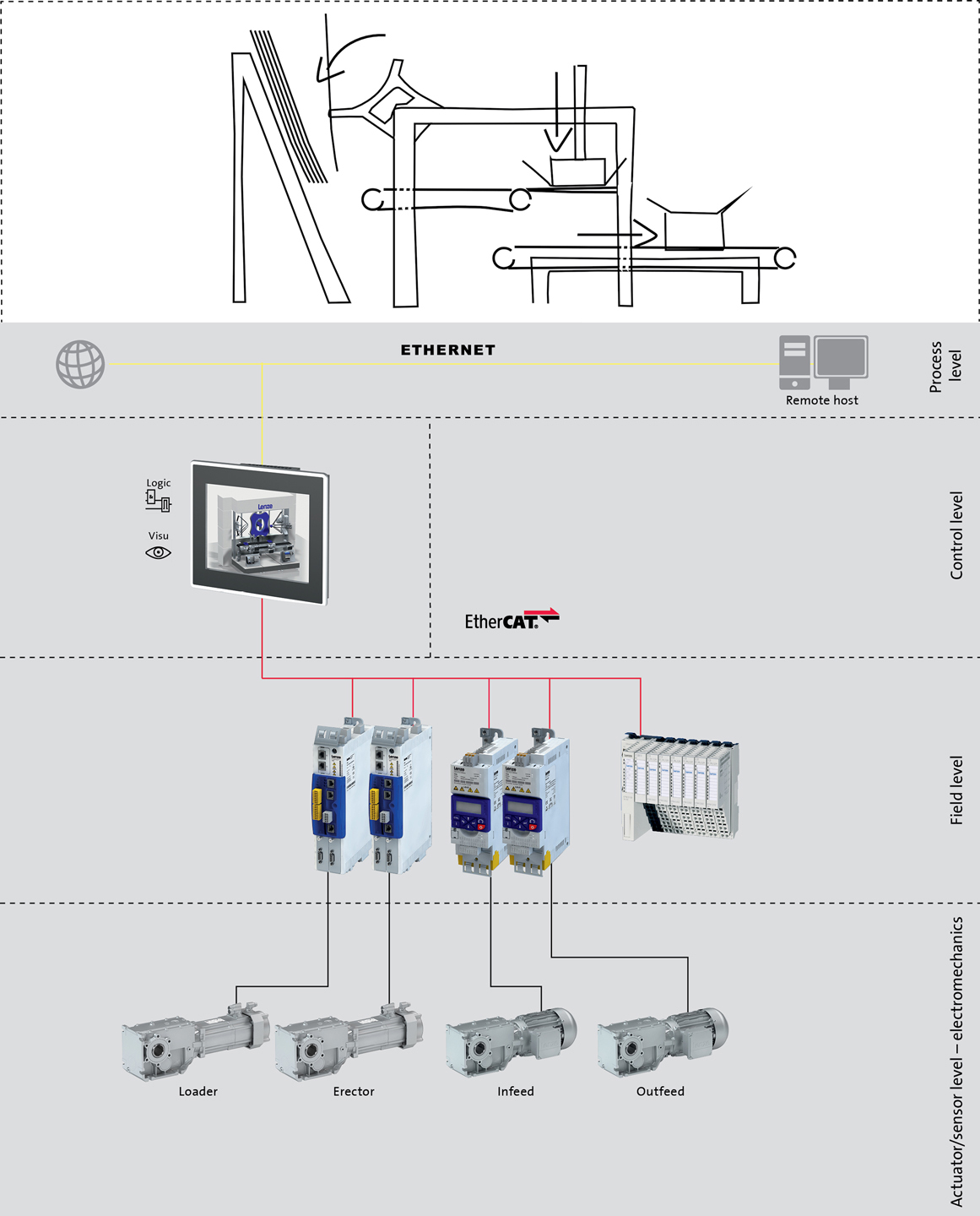

Case packer: The operator is at the centre of things

- Visualisation with an operating concept centered on one user (User Centered Visualization) as well as highly flexible software.

- Intuitive control and navigation by means of language-independent user guidance (use of images and symbols).

- IPC design adapted to the existing machine design, easy user management, secure and easy log-in of the machine operator by means of RFID.

- Fast and reliable set-up, operation and servicing of the machines - worldwide.

- Visualisations on multi-touch displays as well as on different display terminals (mobile phone, tablet, browser, HMI etc.).

- Uniform HMI template and therefore better operability of all machines without any HMI training for individual machines. Standardised view and arrangement of the buttons, error display etc.